- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Flow Meter

- Mass Flow Meter

- Mass Flow Density Meter

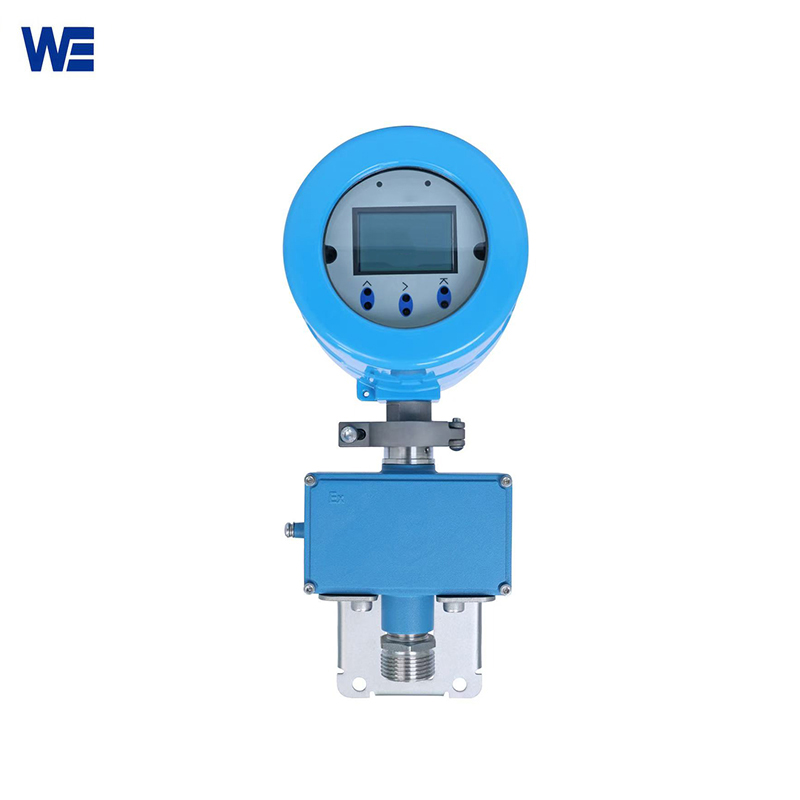

Mass Flow Density Meter

The mass flow density meter adopts a double slightly curved flow tube design with high measurement accuracy. Integrated installation, vertical, inverted, or flag-type installation is adopted according to the site conditions. The flag-type installation has a self-draining function.

![]()

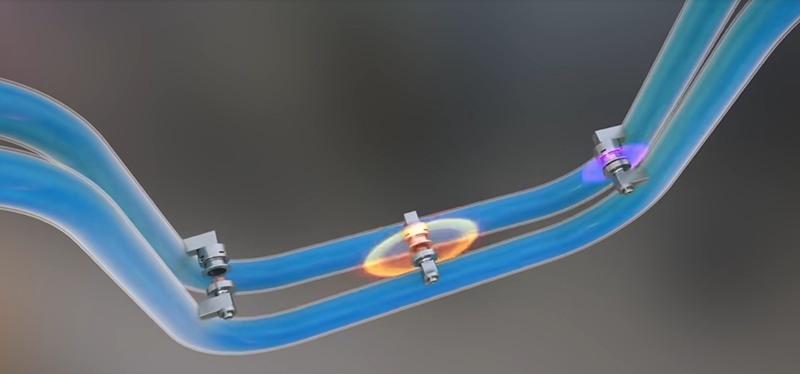

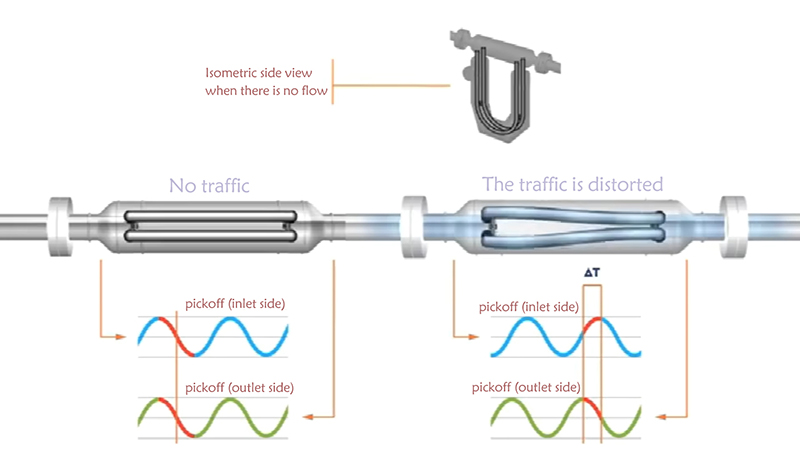

Working Principle of Mass Flow Density Meter

With phase sensors placed on both sides of the pipe input and outflow to detect the phase difference, the flowmeter is equipped with pipes that move at a particular frequency. The Coriolis force deflects the fluid as it passes through, causing a phase shift that alters the pipeline’s vibration frequency. The fluid flow velocity can be intuitively measured since the phase difference between the vibration waves picked up by the electrodes is exactly proportional to it. Furthermore, the fluid’s density can be determined using the vibration frequency since the pipeline’s vibration frequency drops as the fluid’s density rises. Furthermore, the fluid’s mass can be calculated because as its density rises, so does the mass of the fluid passing through the pipe. A temperature sensor that is inserted into the pipeline and used by the flowmeter to detect the fluid temperature intuitively is also included.

Why Choose Mass Flow Density Meter From Wepower?

- The Mass Flow Density Meter adopts a double slightly curved flow tube design with high measurement accuracy. Integrated installation, vertical, inverted, or flag-type installation is adopted according to the site conditions. The flag-type installation has a self-draining function;

- Complete mass flow rate, volume flow rate, density, and temperature measurement and calculation parameters are provided by the Mass Flow Density Meter. The volume table can be immediately substituted, and trustworthy results can be achieved without the need for complex conversions;

- Wepower produces a wide range of mass flow meters, including fourteen models, with flow ranges from 0.035 tons/hour to 1650 tons/hour

Parameters:

| Name | Mass Flow Density Meter |

| DN | 1-300(mm) |

| Temperature display range | -50~+125℃(PT100 temperature measurement element) |

| Medium Temperature | Integrated Type(-40~+125)℃ Separated type(-10~+350)℃ |

| Environment

Temperature |

Storage(-40~+70)℃

Using(-40~+60)℃ |

| Explosion grade | Integrated type:Ex db eb (ib Gb) ⅡC T6 Gb/Extb (ib Db) ⅢC T80℃ Db

Separated type:Ex ib ⅡC T6 Gb/Ex ib ⅢC T80℃ Db |

| Power Supply | 24VDC or 220VAC |

| Output Interface | RS485 , HART |

| Max pressure | Standard1.6MPa、4.0MPa/ Cusomation |

| Signal output | Pulse output + (4~20)mA |

| Accuracy | 0.1%, 0.5%, 0.15% |

| Protection Grade | IP67(Sensor) |

![]()

![]()