- Have any questions?

- +86 15953537010

- admin@wepower-electronic.com

- Home

- Flow Meter

- Magnetic Flow Meter

- Sewage Magnetic Flow Meter

Sewage Magnetic Flow Meter

Sewage electromagnetic flow meters (also called mag meters or magnetic meters), are volumetric flow meters which do not have any moving parts to wear, reducing the need for maintenance or replacement. We are committed to innovative solutions and the highest possible quality in flow instrumentation.

Sewage Magnetic Flow Meter

Sewage electromagnetic flow meter specifically monitors the flow of sewage. The magnetic flow meter has no moving parts or obstructive parts, and there is almost no additional pressure loss in the measurement. The magnetic flowmeter has a wide range up to 1:100, and there are no blocking parts to prevent fluid blockage. The measurement accuracy of the sewage electromagnetic flow meter is not affected by the variety of the measured medium and its temperature, viscosity, density, pressure and other physical parameters.

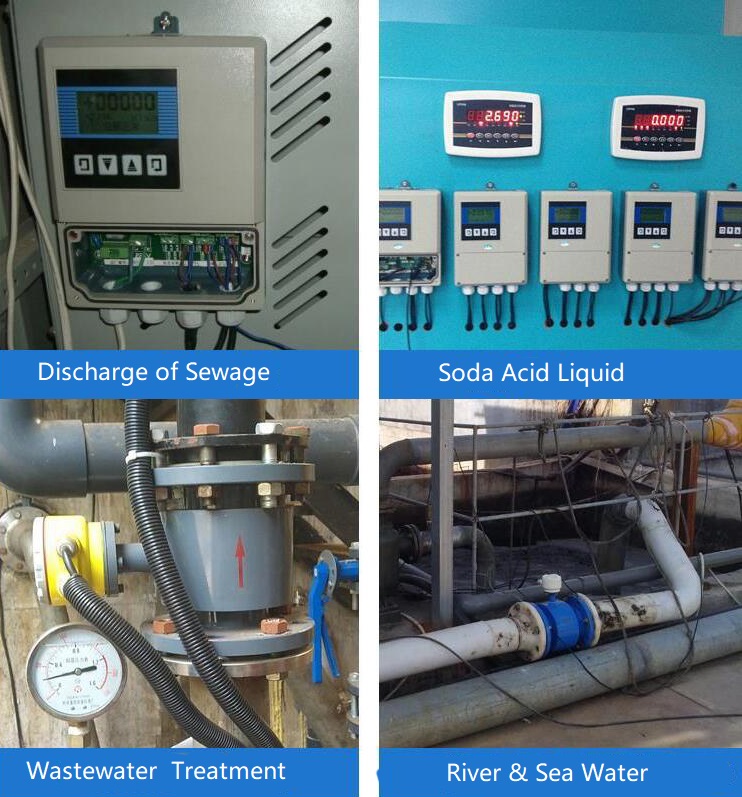

Industrial wastewater and domestic wastewater are the main application areas of electromagnetic flowmeter wastewater. Domestic sewage is mainly various detergents and sewage, garbage, feces, etc. used in urban life, mostly non-toxic inorganic salts. Domestic wastewater contains a lot of nitrogen, phosphorus, and sulfur, and many pathogenic bacteria, while industrial wastewater is much more complicated, involving the production and emission issues of multiple industries. Different combinations of PTFE LINER or rubber raw material and Hc, Hb, 316L, Ti and other electrode materials can meet the needs of different sewage water media.

![]()

| Converter | ||

| Compact Type | IP65 | |

| Remote Type | IP65(IP68 optional) | |

| Measurement sensor | ||

| Nominal Diameter | DN15-DN1000 | |

| Pressure rating (High pressure can be customized) |

DN6 – DN80, PN<4.0MPa | |

| DN100 – DN150, PN<1.6MPa | ||

| DN200 – DN1000, PN<1.0MPa | ||

| DN1200 – DN2000, PN<0.6MPa | ||

| Lining Material | Chloroprene rubber (CR), Polytetrafluoroethylene (PTFE/F4), Fluorinated ethylene propylene (FEP/F46), Teflon(PFA) |

|

| Electrode Material | 316L Stainless Steel, Hastelloy C, Hastelloy B, Ti, Ta, Pt | |

| Ingress Protection | IP68 | IP65 |

| Medium Temperature | -25 – 180℃ | -10 – 80℃ |

| Lining Temperature Range | Rubber liner:-20 …+60℃

High-temp rubber liner:-20…+90℃ PTFE liner: -20…+120℃ High-temp PTFE liner: -2O…+ 160℃ Polyurethane liner: -2O…+ 80℃ PFA: -20 …+180℃ |

|

| Serial communications | RS-485 | |

| Output | Current (4-20 mA), pulse, frequency, state switch | |

| Max measuring error | Measurement value ±0.5%(Flow speed > 1m/s); Measurement value ±0.5% ±2mm/s(Flow speed <1m/s) |

|

| Repetitiveness | 0.15% | |

| Power supply | 100-240VAC, 50/60Hz, 22VDC-26VDC | |

| Power consumption | Max 15VA | |

| Signal cable | Apply only to remote type | |

| Shielded cable | Signal section, wire: 0.5mm2 Cu /AWG20 | |

Sewage Magnetic Flow Meter Flow Range Table

| Size | Min flow m³/h | Normal flow rate m³/h | Max flow m³/h | |

| DN15 | 0.06 | 0.19 | 3.18 | 6.36 |

| DN20 | 0.11 | 0.33 | 5.65 | 11.31 |

| DN25 | 0.17 | 0.53 | 8.83 | 17.67 |

| DN32 | 0.28 | 0.86 | 14.47 | 28.94 |

| DN40 | 0.45 | 1.35 | 22.61 | 45.23 |

| DN50 | 0.71 | 2.12 | 35.35 | 70.68 |

| DN65 | 1.19 | 3.58 | 59.72 | 119.45 |

| DN80 | 1.81 | 5.42 | 90.47 | 180.95 |

| DN100 | 2.82 | 8.48 | 141.37 | 282.74 |

| DN125 | 4.41 | 13.25 | 220.85 | 441.71 |

| DN150 | 6.36 | 19.08 | 318.08 | 636.17 |

| DN200 | 11.31 | 33.92 | 565.48 | 1130.97 |

| DN250 | 17.67 | 53.01 | 883.57 | 1767.14 |

| DN300 | 25.44 | 76.34 | 1272.34 | 2544.69 |

| DN350 | 34.63 | 103.91 | 1731.8 | 3463.6 |

| DN400 | 45.23 | 135.71 | 2261.94 | 4523.89 |

| DN450 | 57.25 | 171.76 | 2862.77 | 5725.55 |

| DN500 | 70.68 | 212.05 | 3534.29 | 7068.58 |

| DN600 | 101.78 | 305.36 | 5089.38 | 10178.76 |

| DN700 | 138.54 | 415.63 | 6927.21 | 13854.42 |

| DN800 | 180.95 | 542.86 | 9047.78 | 18095.57 |

Sewage Magnetic Flow Meter Comparison Sheet of Lining Material Properties

| Lining Material | Short Name | Specification | Temperature | Medium |

| Neoprene | CR | Medium wear resistance, resistance to general low concentration of acid and alkali salt solution corrosion | 0 ~ + 65 ℃ | Tap water, industrial water, sea water |

| Polyurethane (pu) | PU | Excellent wear resistance, acid and alkali resistance | 0 ~ + 65 ℃ | Pulp, pulp |

| Teflon | F4

(PTFE) |

Stable chemical properties, can withstand boiling hydrochloric acid, acid, aqua regia, strong alkali corrosion | – 25 ~ + 140 ℃ | Corrosive acid and alkali solution |

| Polyperfluoroethylene propylene teflon (FEP) | F46

(FEP) |

The chemical properties are equal to F4, and the compressive and tensile strength are superior to F4 | – 25 ~ + 120 ℃ | Corrosive acid and alkali salt solution |

| Soluble ptfe | PFA | Chemical performance is equal to F46, compression and tensile strength is better than F46 | 0 ~ + 180 ℃ | Corrosive acid and alkali salt solution |

| Alumina ceramics | Ceramic | Excellent wear resistance (more than ten times that of polyurethane and rubber), excellent corrosion resistance (suitable for the measurement of strong corrosive fluids such as mixed acid and aqua aqua, but not suitable for high concentration of alkaline, phosphoric acid, hydrofluoric acid and cyanide compounds), extremely high hardness and finish, excellent heat resistance and heat shock resistance. | 0~+250℃ | Especially suitable for high temperature, high pressure grout, food hygiene and corrosive fluid medium measure |

![]()

![]()

![]()